DenimWorks purchases its denim from a local supplier with terms of net 30 days, FOB destination. This means that title to the denim passes from the supplier to DenimWorks when DenimWorks receives the material. Any difference between the standard cost of the material and the actual cost of the material received is recorded as a purchase price variance.

Current standards

Under this process, the inventory cost is close to the actual cost. Thus, material, labour, and overhead costs as well as the inventory of raw materials are shown at actual costs; the cost of goods sold and inventory of finished goods and WIP are shown at standard costs. The production that is acceptable (not rejected products) and which Accounting Periods and Methods is assigned manufacturing costs of direct materials, direct labor, and manufacturing overhead.

- Since the process of standard costing allow an appraisal to be made of personnel, machines and method of working, current inefficiencies come to the notice and get eliminated.

- These costs are treated similarly to organizational overheads and not related to products or other cost objects, such as customers.

- DenimWorks purchases its denim from a local supplier with terms of net 30 days, FOB destination.

- (a) Setting of standards and construction of a budget based on them.

- Standard cost is a planned cost for a unit of product, component or service produced in a period.

- Variances between actual and standard are reported for investigation and corrective actions are taken to remove the causes of adverse variances.

Not Suitable for Fast-Paced Environments with Regular Price Fluctuation

- Since the organisation takes note of all inefficiencies and setbacks, these costs can be used for planning inventories and forecasting cash flows.

- We indicated above that the fixed manufacturing overhead costs are the rents of $700 per month, or $8,400 for the year 2024.

- Past records can be used only to assess ‘normal’ wastes, machine breakdown, level of efficiency, etc.

- Standard Costing is a tool for the management to gain reduction in the cost and control over it.

- This standard is not in common use, because in the face of rapid changes in operating conditions, such a standard cannot be of any real help in developing current standards.

- The system may not be suitable for small concerns since in their case careful scheduling of production may not be possible.

- The company expects that the cost will not change over the full cycle.

Standard costing involves the setting of predetermined cost estimates in order to provide a basis for comparison with actual costs. A standard cost is a planned cost for a unit of product or service rendered. Standard costing is universally accepted as an effective instrument for cost control in industries. The cost accountant may periodically change the standard costs to bring them into closer alignment with actual costs. With standard costing, the general ledger accounts for inventories and the cost of goods sold contain the standard costs of the inputs that should have been used to make the actual good output.

To Establish the Principle of Management by Exception

If an investor expects 8% in an inflation free world, he would expect 12% rate of return on investment in a world subject to inflation pressures. The rate of inflation will have its impact on future cash-flows and profitability of the concern. Before any estimates made or standards set, the difference between money rate of interest and real Accounting for Marketing Agencies rate of interest, the difference between them should be taken as rate of inflation.

- 7) Facilitate Co-ordination – When standards are fixed, the performance of various departments e.g., production, sales, purchase etc., is considered.

- As the name suggests, it bases on the assumption of the basic nature of company business over a long period of time.

- Using standard costs makes the calculation of stock (inventory) easier.

- This is due to variation in the price of raw materials, production delays, changes in salaries/ wages, etc.

- Standard cost helps to prescribe standards and the attention of the management is drawn only when the actual performance is deviated from the prescribed standards.

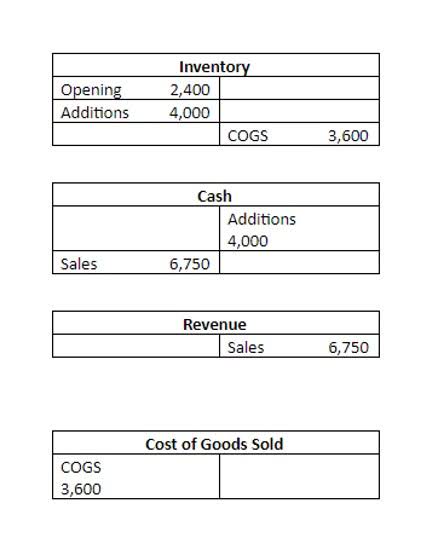

When we make the journal entries for completed aprons, we’ll use an account called Inventory-FG which means Finished Goods Inventory. We’ll also be using the account Direct Materials Inventory or Raw Materials Inventory or Stores. Most manufacturers will also have an account entitled Work-in-Process Inventory, which is commonly referred to as WIP Inventory. Since the calculation of variances can be difficult, we developed several business forms to help you get started and to understand what the variances tell us.

It aims at measuring the performance, controlling the deviations, inventory valuation and deciding the selling price of the product especially when quotations are prepared. Under this plan WIP control account is both debited and credited at standard costs and inventory of raw material, WIP and finished stock is valued at standard cost. Variance analysis, an standard costing essential component of a standard costing system, cannot be applied on a product to product basis for administration, selling, and distribution overheads.

Ascertainment of actual costs

In order to use predetermined standard costs, standards have to be set for each element of cost for each line of product manufactured or service supplied. Standard cost shows what the cost should be keeping in mind the most favourable production conditions, and on the assumption that plant will operate at maximum possible efficiency. The most important objective of standard cost is to help themanagement in cost control.